Addressing industrial cybersecurity risks affecting the industry

ANDRITZ partners with OTORIO to safeguard production operations

The pulp and paper industry continues its rapid digital transformation. This makes pulp and paper manufacturers’ industrial networks more connected, more productive — but, unfortunately, more exposed to cybersecurity risks. Safeguarding IT and operational technologies (OT) is critical to ensuring business continuity and resilient operations at the heart of pulp and paper manufacturing.

As industry leader ANDRITZ’s OT cybersecurity partner, OTORIO knows how crucial safety, uninterrupted energy supplies, plant operations, and reliable utilities are to the pulp and paper manufacturing processes. The sophisticated industrial machines crafted by ANDRITZ rely on multiple technologies, data sources, automation, and digitalization, as well as procedures to optimize process performance.

Manufacturers worldwide have been hit with real-world industrial cybersecurity attacks that halt industrial operations, lead to ransomware demands, harm business continuity, and affect shareholder value. The pulp and paper industry is no exception. Over the past two years, cyber attacks have impacted the manufacturing operations of at least three different paper and packaging companies in North America and Europe.

Whether they deal with recycling OCC, packaging board, and mixed waste, securing production lines, drying processes, or power and boiler generation, OTORIO’s industrial-native cybersecurity solutions enable pulp and paper manufacturers to minimize digital and cyber risks to their industrial operations. OTORIO’s solutions prioritize risk mitigation, add business context, and allow plants to manage multi-site OT, IT, and IIoT networked environments from one central dashboard.

WHY THE INDUSTRY FACES CYBERSECURITY VULNERABILITIES

Whether producing paper, boards, or tissue, the various stages of pulp and paper production and the technologies that support it increase a manufacturer’s digital attack surface. Producing panelboard, for example, involves heavy industrial machinery and automated, networked technologies for raw wood processing, preparation, cleaning, and pressurized refining. If a cyber attack impacts even one stage of the process, this can have a domino effect on related processes, potentially disrupting or halting operations until the security breach is resolved.

PROVEN CYBERSECURITY VALUE FOR INDUSTRY CLIENTS

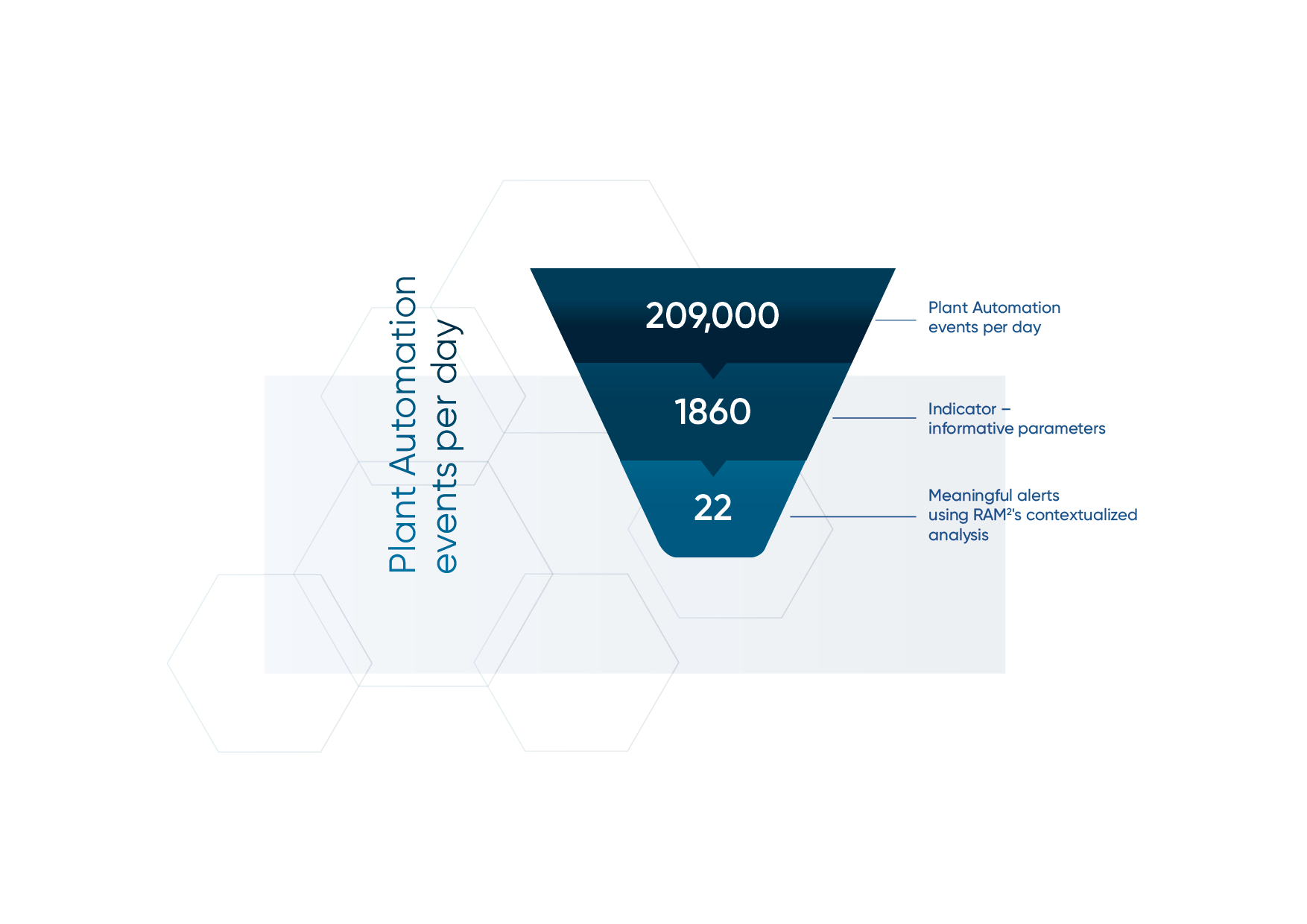

OTORIO has extensive, proven experience working with global pulp and paper industry manufacturers to assess, monitor, and manage digital risk. This includes ensuring comprehensive visibility of industrial assets, reducing ‘noise’ caused by high volumes of false-positives and irrelevant OT security alerts, prioritizing the mitigation of industrial cybersecurity risks based on their context, and potential impact on your business.

OTORIO has experience reducing ransomware risks and helping companies fight phishing attempts that target thousands of employees at hundreds of worldwide locations. It leads to improved customers’ security controls to ensure their OT, IT, and IIoT network environments are resilient against future attacks.

OTORIO has extensive experience performing vulnerability and penetration testing (‘pen testing’) for pulp and paper manufacturers.

Plant Automation events per day. Indicator – informative parameters. Meaningful alerts using RAM²’s contextrualized analysis

© ANDRITZOTORIO AND ANDRITZ HELP SAFEGUARD YOUR OPERATIONS

ANDRITZ helps its global pulp and paper customers minimize digital and cyber risks through its partnership with OTORIO. Founded by leading OT cybersecurity experts, OTORIO’s portfolio of industrial-native cybersecurity solutions ensures continuous digital risk management and compliance. These solutions are now fully integrated into the ANDRITZ Automation & Digitalization portfolio, providing customers with safer machines and a significantly more resilient infrastructure.

In a multi-generational, constantly changing threat environment, customized OT cybersecurity measures are an critical part of the automation development process. That is why ANDRITZ embeds OTORIO’s innovative solutions in it market-leading solutions and services, ensuring that every pulp and paper machine meets the highest cybersecurity standards. The advanced services are delivered in the safest way, ensuring the customer’s continuous efficient and effective production, along with proprietary commercial data security.

In today’s rapidly evolving industrial operations environment, protection against cybersecurity risks and compliance with industrial security standards is expected with every machine delivery and commissioning. ANDRITZ ensures that each machine it delivers is secure, regulatory compliant, and meets the customer’s contractual requirements for continuous, safe production.

With OTORIO’s spOT Lifecycle solution, ANDRITZ can also provide post-delivery Security-as-a-Service over the machine’s entire lifecycle on the customer’s premises. spOT Lifecycle periodically checks configurations and vulnerabilities during ANDRITZ service calls (whether remotely or on-site), and performs “virtual querying” of the machine’s fingerprint for new, publicly-known vulnerabilities. This solution provides clear, practical recommendations on how to remediate compliance and security gaps and harden against ransomware attacks.

The result is a detailed report on compliance confirmation that delivers accurate, in-depth security verifications of the delivered machines. spOT Lifecycle enables ANDRITZ to remediate each vulnerability, security gap, and compliance deviation prior to a machine’s delivery, and include details on any mitigation steps taken in the issued report. The information is also used to ensure that new deliveries are secure by design.

ANDRITZ’s Automation & Digitalization embeds OTORIO cybersecurity into the automation lifecycle of new and existing machines for safe, resilient, and efficient operations. The company’s Security-as-a-Service offering ensures that each machine it delivers is secure, regulatory compliant, and meets contractual requirements. Every customer is assured that ANDRITZ deliveries provide continuous, safe production throughout their entire lifecycle.

For secure remote access to operational assets, ANDRITZ Automation & Digitalization utilizes OTORIO’s remOT to deliver secure, simple, and fully governed remote access to the operational environment.

ANDRITZ applies remOT zero trust security architecture as a service in customers industrial environments in compliance with IEC standards for single sign-on controlled access to operational assets. Alternatively, clients can easily manage remote connections for all their third-party vendors by using remOT.

COMBINED EXTENSIVE EXPERIENCE IN MANAGING INDUSTRIAL RISK

Industrial cybersecurity risks and ransomware demands affecting pulp and paper manufacturers’ production are an unfortunate reality. Companies must proactively assess, manage, and mitigate OT security risks to protect business continuity and maintain resilient operations.

OTORIO and ANDRITZ bring their extensive experience and industrial-native cybersecurity expertise to help you assess, monitor, and manage industrial risks. From helping to ensure safe pulp and paper manufacturing operations to reducing risks and vulnerabilities that can impact your production, worker safety, critical infrastructure, and regulatory compliance, our combined proven OT security solutions and services can enhance your cybersecurity posture and help safeguard your industrial production.